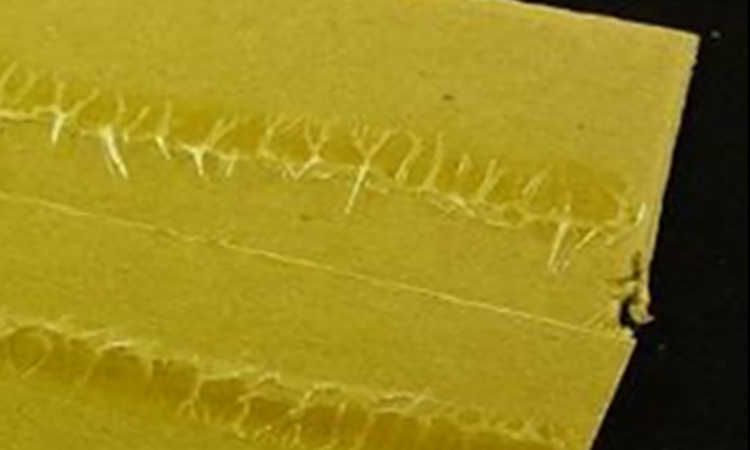

Foamy glue in buckets

THE ORIGIN OF THE PROBLEM

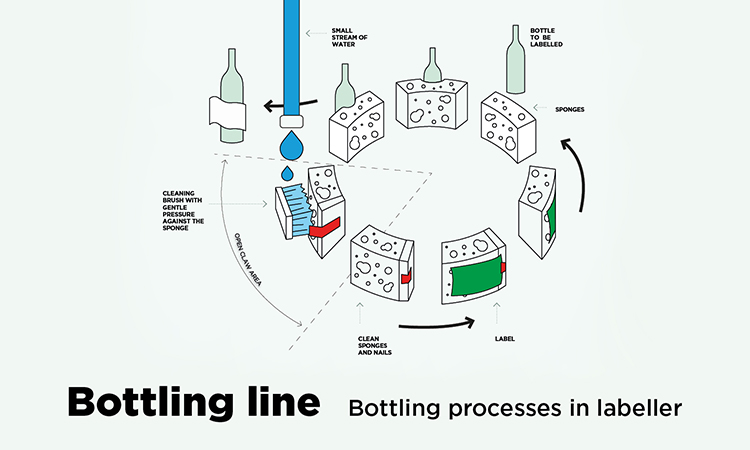

It occurs when there is a large loss of water in the glue, which can result in an excessive increase in viscosity, when one or more conditions occur:

- Excessive duration of the glue bucket

- Excessive shake of the glue: loss of water and incorporation of oxygen to the glue

- High pumping flow rate: greater than 1Litre / minute (Optimum flow rate 0.5litres / minute)

- Glue with low machine stability

THE SOLUTION

It is essential to use a glue whose properties related to machine stability are appropriate for the different labeling conditions.

The glue machine stability is a characteristic, in which the ability of the adhesive to maintain a stable tendency of its viscosity during its use in the machine is mainly assessed.

Other characteristics such as density are also taken into account, due to the incorporation of air caused by the shake that confers the spongy appearance of the glue in these cases.